Ukuphrinta kokushisa kokushisaIngabe inqubo, njengesixhumanisi esibalulekile kuyo yonke inqubo yokuphrinta, ihlobene kakhulu nezinye izixhumanisi, ukuthi ungalawula kanjani ukuqina kwenqubo kuyisiqinisekiso esibalulekile sekhwalithi yokuphrinta. Ngezansi, ake sibheke izinto ezibalulekile ezithinta inqubo yokuphrinta yokushisa yokushisa.

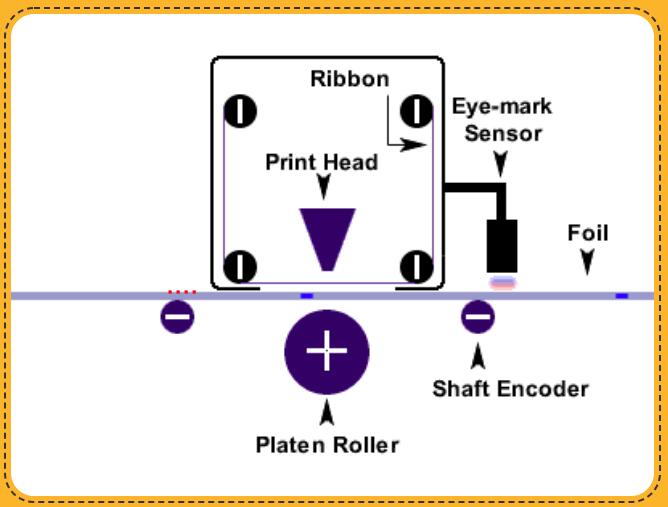

1. Heater Printer Head

Le khasiukuphrinta ukushisaIkhanda ikakhulukazi liqukethe ungqimba oluvikelayo lwefilimu olungaphezulu, isendlalelo esivikelayo sefilimu esiphansi kanye nezinto zokushisa.

Isivinini sokuphrinta sokushisa sincike esikhathini esidingekayo somugqa ngamunye wombhalo. Ngakho-ke, ikhanda lokudlulisa ukushisa nokudlulisa kufanele kube nokusebenza okuhle, ukuze ukushisa okukhiqizwe yinto yokushisa kungadlula ngokushesha ungqimba oluvikelayo, kudlulise iphepha elingaphansi kwegebe, ukuze liqinisekise ukuthi uyinki we-substrate isikhathi sokudlulisa esanele.

2. Uyinki

Ukwakheka kwe-inki yokuphrinta okushisa okushisa ngokuvamile kungumbala (upende noma udayi), i-wax kanye namafutha izingxenye ezintathu

Lapho ukuphrinta, i-viscosity ye-inki ehlukile ihlobene ngqo nokushisa okufudumeza, futhi izinga lokushisa lokushisa kufanele lilawulwe ngokuqinile nokuvunywa yi-ink.

3. Dlulisa iphepha

Ukusebenza okuhle okushisayo ngenxa yesipiliyoni sokudlulisa kufanele kuqedwe ngokushisa okuphezulu, ngakho-ke okuqukethwe kwephepha lokudlulisa kufanele kuvunyelwe ukubekezelela umthelela wokushisa okudluliswayo, izakhiwo eziqhubekayo ezingashintshiwe. Ngokuvamile, ukusebenza okushisayo kwezinto eziyisisekelo zephepha lokudlulisa le-thermal, ezingabonakala ngezinto ezilandelayo:

a. Ukumelana okuphansi okuphansi kanye nokuncipha kwe-substrate, okungcono ukusebenza kokufuduswa kokushisa.

b. I-Smoother of the substrate ebusweni, okungcono ukusebenza kwe-thermal.

c. Ukuvikelwa kokushisa okushisayo okushisa okushisayo kuvame ukuba ngu-300 ℃, impahla eyisisekelo kumele ikwazi ukuqinisekisa ukuthi ukusebenza okuyinhloko akuguquki kulokhu kushisa.

4. Ama-substratesngaphezulu

Isipiliyoni sibonisa ukuthi kancane indawo evuthayo engaphezulu kwekhwalithi yokuphrinta yinhle, lesi isici esisobala sokudluliswa kokushisa. Ngoba indawo evuthayo ye-substrate ikhombisa ukuthi i-substrate inamandla amakhulu, i-ink ephepheni lokudlulisa ingadluliselwa kahle ku-substrate, uma iqhathaniswa neleveli ekahle nokuhleleka; Kepha kukhale kakhulu kuzothinta ukudluliswa okujwayelekile kwe-ink, akukuvumeli ekuphothulweni kwenqubo yokuphrinta.

Isixhumanisi se-Clikc ngezansi, ungathola ofanelekayoAmalebula wokudlulisa ukushisaUdinga.

https://www.colorpglobal.com/heat-transfer-labels-product/

Isikhathi sePosi: Jun-20-2022