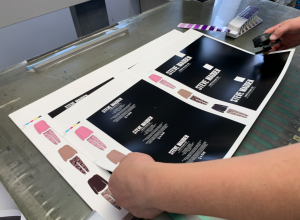

In the daily production process, we often encounter the problem that the color of printed matter mismatches the color of customer’s original manuscript. Once meet such problems, production personnel often need to adjust the color on the machine for many times, which causes a lot of waste of working hours of printing enterprises.

It is necessary to analyze the reasons of mismatching in the printing process to solve the problem pertinently. Here, we’d like to share some common reasons if this printing problem in production process with you.

1. Plate-making

Generally speaking, we need to make second corrections to the original electronic files provided by customers in prepress plate making, for some of the prepress output may encounter “traps” that need necessary corrections, in order to avoid real problems in the output. One of the most important steps is to adjust the color of the manuscript, because in the actual printing process need to consider the dot deformation rate. An experienced prepress producer can adjust the color of the source file according to the characteristics of the machine itself to make the color of the printed file more like the original, but this requires a long time of experience.

2. Printing pressure

As we know, the size of printing pressure can also affect the size of dot deformation. If the printing pressure is too large, the dot will become larger; If the printing pressure is too small, the dot may become smaller or even false printing. Under normal circumstances, the dot deformation rate caused by printing pressure is generally between 5% and 15%.There are many ways to judge whether the printing pressure is appropriate, among which the more commonly used is to monitor the printing pressure with GATF.

3. Ink quantity control

When the dot on the printing plate and the dot size of the original within 10%, by adjusting the ink volume can achieve the color of the printed matter and the original color close, when the color is dark need to lower the amount of ink, when the color is dark need to increase it. When using this method for debugging, pay special attention to the following two issues: a. Remove ink when the color is particularly dark 2. Avoid conflicts on the same ink channel in production

4. Ink color

Different ink manufacturers use different pigments, ink hue will probably has a difference. If the customer manuscript is not printed with the same ink manufacturer as the printing enterprise, the color of the printed matter is likely to have a color difference problem. This situation only exists when the above reasons are eliminated, and the printing color difference is very small. This chromatic aberration is generally acceptable, but if the client is very strict, it may be necessary to print with the same ink as the client’s original.

The above are several common reasons for the difference between the color of printed matter and customer’s original manuscript in the process of label printing. Of course, there may be some complicated problems in the actual production process, Color-p is willing to share printing technical problems with you and help you solve the problems you may encounter in the production of packaging printing.

Post time: May-19-2022