Clothing bag is used to pack clothes packaging bag, many brand clothing will design their own clothing bag, clothing bag design should pay attention to time, local, and the expression of commodity information, can use the line arrangement and text, picture combination. The following is through the material to understand the clothing bag.

- 1. HDPE/ LV PE/ LV film

This is the most common material, shopping bags can often be seen in supermarkets, is made of HDPE bags. This material can be made into separate bags, which is a relatively common and cheap material on the market. This kind of packaging bag is more brittle, harder, low expansion rate, knead the sound is more brittle.

- 2. LDPE-low density polyethylene/high pressure polyethylene/high pressure film

The bag of this material is of good quality, soft, good toughness, good transparency, feel more slippery, the thicker the bag is, the harder the expansion rate is. This kind of material can also be made into individual bags, which is a relatively common and cheap material like PO bags.

This material is with brittle and high transparency in the pillow core zipper bag. The tension is not enough, it can be said that there is no tension at all, and the printing is easy to decolorize. It needs to be placed for a period after printing, and then the bag is cut.

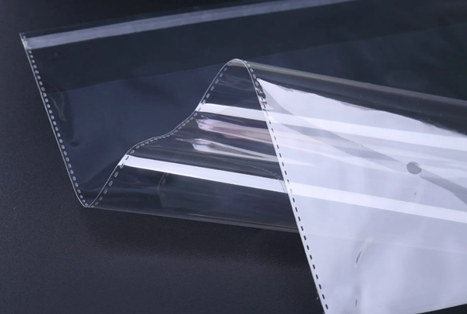

- 4. CPP/ flow polypropylene/terminal stretch polypropylene

This material has high transparency, high hardness than PE film, relatively clear, often used as the base film of composite materials, often combined with other films into bags, is a good composite film. CPP also has a cooking grade material that can be used to make cooking bags.

- 5. PET/ polyethylene terephthalate

This material is also with very good transparency, strength and toughness is better than polystyrene and PVC, not easy to break, smooth and shiny surface. It is also one of the common composite materials.

- 6. PA/Nylon

This material often do cooking bag/boiling bag composite material, good toughness, relatively soft.

- 7. Aluminum Foil / AL

Aluminum foil is made of high purity aluminum after many times of calendaring. It is an excellent heat conductor and light shield. Good mechanical strength, light weight, no thermal bonding, with metallic luster, good shading, strong reflection of light, not easy to be corroded, good barrier, moisture-proof and waterproof, strong air tightness, and has aroma retention. Metallic luster, gas barrier, adhesion viscosity is not high, after composite processing is easy to appear aluminum layer transfer phenomenon.

Post time: Apr-11-2022