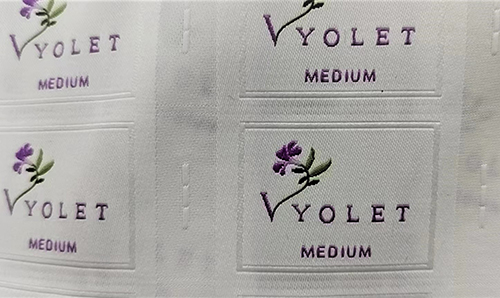

First of all, to check the pattern text of the woven label. The pattern and text on the label should be exactly the same as original pictures or layouts. This is rather important to meet customers’ needs. The pattern made should not only meet the requirements in shape, but also in size. The woven label itself is very small, and the size of the pattern sometimes needs to be accurate to 0.05mm.

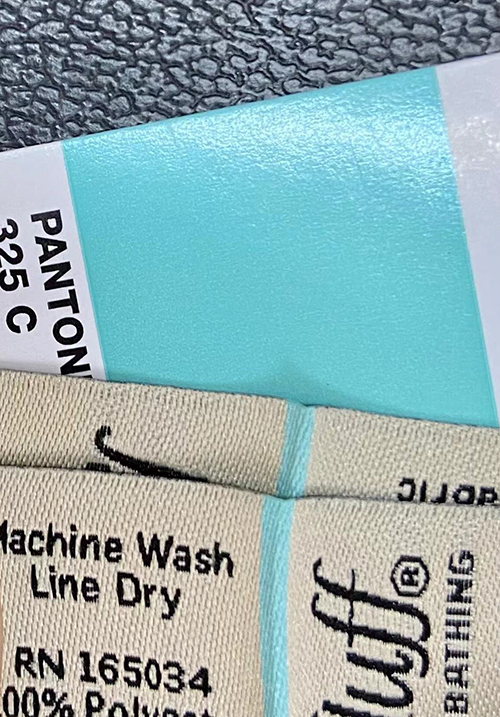

Secondly, you should check the woven label colors. The color is generally selected from Pantone color system. The color contrast here is the color number of the original layout color or the Pantone color of the design draft. It depends on the yarn dyeing crafts, and we generally meet several times of color revision which can only be judged by the senses of different customers.

Third, to check density of the woven label yarn. The density of woven label refers to the density of weft. The higher density of weft, the higher quality of woven labels. Weft density refers to the number of yarns in the 1CM woven label. And to judge the yarns, they are usually denoted by D, from 100D to 30D to present different thickness. It depends on the detailed requirements of customers.

Fourth, to check the post-processing of the woven label. The following procedures of the woven label generally include hot cutting, ultra-cutting, folding, ring mold, starching (, the woven mark will become stronger after this process), and edge locking (that is, to seal the sides of the woven label in case of the loose edge).

These post-processing determined whether finish appearance after knitting is fine. Whether you need your woven labels to be soft or solid, shiny or understated, Color-P has a proven process to match your needs.

Just click here to contact our sales. And with easy steps, you will have your own custom woven labels

Post time: Nov-21-2022